The Unbearable Lightness of Productivity

What a visit to a magnet factory in Oxfordshire teaches you about the state of the world, the race for minerals and the obscure processes happening all around us

One of the best things about my day job is that I occasionally get to visit places no-one else gets to see. As a TV reporter I am allowed into factories and workplaces around the country to meet all sorts of people doing the jobs that, multiplied up on a grand scale, comprise “the economy”.

The problem is that all too often the most interesting stuff one discovers on such visits ends up on the cutting room floor. Invariably when one is dispatched to a particular plant or location it is in the pursuit of a bigger story, towards which each “case study” can only provide a smallish component: a minute or so of pictures, words and interview, invariably about abstract stuff.

In short, I often find myself in utterly fascinating places where few outsiders ever go, learning all sorts of amazing stuff about this or that sector, but since the story of the day is inflation or trade figures or Brexit or whatever, the complex story about what their business actually does often gets left behind. We kind of just need to hear what they have to say about the story of the day, and that’s about it.

If you’ve read Material World, you’ll recall that in one respect the entire book is the unintended consequence of one of these assignments - when I travelled to a gold mine in Nevada in an effort to make a point about the way gold transactions distort Britain’s trade data.

The main thing that struck me about the experience was the vastness of the mine and the destructiveness of the process - the sheer amount of rock you need to move to produce a single gold bar. But since none of that was especially relevant to the film I was making, it didn’t really merit a mention. It just started gestating - and then the idea behind the book began to coalesce.

All of which is to say, while the stuff I get to put on TV might well be the most “newsworthy” it’s not always what you might consider the most fascinating. Invariably it isn’t. A case in point is last Friday. A few hours after the latest GDP data were released a few of us broadcasters were dispatched to a secret location in Oxfordshire to do some interviews with the Prime Minister.

We only get five minutes and naturally most of my questions - and those of my colleagues - were about the “newsworthy” stuff. The fact that the UK had come out of recession, about the real underlying state of the economy (not quite so good) and the Conservatives’ poll ratings (very much not good).

But, and I mean this with all due respect to Rishi Sunak, the business we were sitting in was far, far more interesting than anything that came up in the interview.

The chances are you haven’t heard of Siemens Healthineers, or maybe even the main product they make: superconducting magnets. But it turns out this company, located close to Oxford, is one of the world’s biggest producers of superconducting magnets.

These days Britons tend to assume that the country has deindustrialised to such an extent that we don’t make anything anymore. But while deindustrialisation is certainly happening, here’s an example which bucks the trend - of something the UK is very, very good at making.

Superconducting magnets are incredibly complex bits of machinery, which run a lot of power through niobium tungsten wires (sometimes shrouded in copper) to create an incredibly strong electromagnetic field. Magnetic force is measured in Teslas. The kind of magnet you get inside a refrigerator might have around 0.001 Tesla; those small bar magnets you probably remember from classroom experiments with iron fillings is roughly 0.01 Tesla.

But the kinds of magnets they make at this plant are many, many multiples of that - 1.5, 3 and 7 Tesla magnets. These are extraordinary pieces of machinery with an incredibly important purpose, because the main use for them is to power MRI scanners around the world.

Magnetic Resonance Imaging is one of the most important healthcare technologies in the world, helping save millions of lives each year by allowing doctors to scan inside the organs of a living patient. And even today roughly a third of all MRI scanners are made (or rather, the magnet that comprises the core of the MRI scanner) in that factory in Oxfordshire. Here is one of those fields where the UK is genuinely a world leader - not just in design or engineering but in manufacturing.

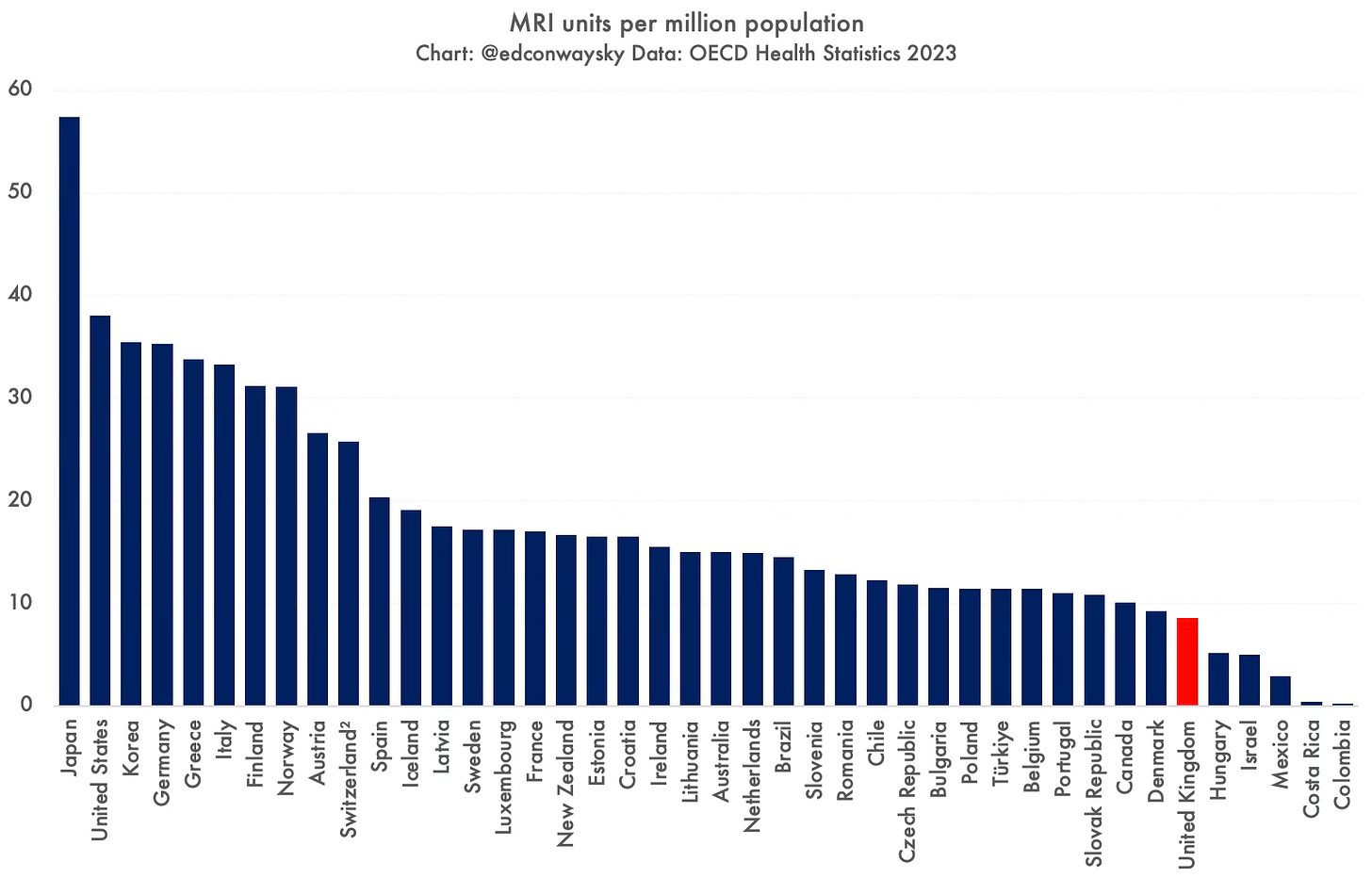

It’s perhaps worth pausing at this moment to reflect the bizarreness of the situation that the UK, one of the world’s biggest producers of the key technology inside MRI scanners, has far fewer MRI scanners available to the population than nearly every other developed economy in the world. Just look at the chart above. We make the stuff - we then ship it overseas. But that’s a whole other story, about the NHS and capital spending, for another day.

Anyway, when you visit the plant and see these machines being built, you’re immediately struck by a couple of things. First, they are mostly all being made by hand. There are some robots here and there, but it’s striking how much of the work is manual - by highly-skilled technicians.

Second, the magnets are big - I mean, seriously big. They need to be lifted by cranes into place, have to be carried in specialist trucks. Third, they are covered in labels warning that they contain liquid helium.

Why? That comes back to technology inside these units. In order to create a superconducting force along the wires inside these units, they need to be cooled to a few degrees above absolute zero. And helium, which boils at -269 degrees C, is precisely the stuff you need to keep those wires at the appropriate temperature. Until we manage to develop high temperature superconductors, we will continue to need lots of helium to keep these magnets working - and to keep MRI scanners going.

Helium is one of those elements few people spend much time thinking about, until they need to fill up the balloons at a children’s party. But while helium is very abundant around the universe (it’s actually the second most plentiful element in existence) on earth it’s actually rather scarce. It gets produced naturally when uranium or thorium in the planet’s crust decay, but this happens at such a slow rate that in practice, the amount of helium here on earth is essentially finite. It is also - like most other things (back to the book) mined.

In a few gas fields around the world - in the US, Algeria, Qatar, Russia and Australia, helium is encountered alongside the natural gas, and then processed and separated by the producers. The problem is that as far as anyone can tell there is significantly less helium under the ground than there is natural gas. And we’re running it down. Australia’s only helium plant was shut last year because there wasn’t enough helium coming out of the ground.

Now, there’s still plenty of helium coming from the US and Qatar (the US has been producing helium, much of it from Texas, for coming up to a century now). But there’s only a relatively small number of places producing the gas. Every so often one or other of those plants shuts down due to technical reasons and the helium world panics. Prices rocket and everyone fears they will have to turn off their MRI scanners.

Because as the US Geological Survey puts it, “Nothing substitutes for helium in cryogenic applications”. Oh and once you’ve released helium out into the atmosphere, it’s gone. There’s no getting it back. So this stuff really matters (and that’s before you consider the importance of helium for nuclear research and all sorts of other applications).

Anyway, long story short: helium is about far more than floating balloons and squeaky voices. It’s a really big deal. And about a quart of the world’s helium is currently used by MRI scanners. A typical 5 Tesla scanner might contain 1,000 litres of helium at any one time. And since that helium sometimes evaporates off, they also need to be constantly kept refilled. You might be talking about 10,000 litres for an MRI scanner over its lifetime, which is, well, a lot of helium. If we carry on using helium at the rate we are, and then consider all those countries who need more MRI scanners (like, erm, the UK), then it’s near inevitable that we have more helium shortages and panics in the future.

So, back to the factory in Oxford. Once upon a time the main thing the researchers at this factory (and other superconducting magnet factories) were focused on was making ever more powerful magnets - getting higher field strength, higher gradients, more field channels and so on. More, more, more.

But these days there’s another focus: how to make scanners that consume far less helium. And the big news last week, coinciding with the PM’s visit, was the plan for a new plant which will enable them to make a new range of MRI scanners which consume far, far less helium - less than 0.7 litres per scanner (which is an astounding achievement given the typical scanner these days uses hundreds of litres).

Smaller scanners with less helium mean you can potentially put those scanners in more places. You no longer need to install them with cranes. You no longer need to install special chimneys and vents for the helium. You can put scanners in places (small surgeries, walk in centres etc) where you might never previously have needed them. Cutting helium consumption potentially democratises MRI scanner availability, which could in turn save millions more lives.

But what struck me as I chatted to the technicians about all of this were the analogies with some of the technologies I discussed in Material World. Take semiconductors. For decades, the obsession among chip makers was producing ever more powerful silicon. But in recent years the focus has shifted to producing ever more efficient chips. Or consider the analogies with the car paint industry, where these days the focus is just as much on reducing the amount of volatile compounds in car paint as it is in improving the performance of the coatings.

As I write in the book, one of the great wonders of the modern world is that the more time we spend making things, the better we get at it - this is Wright’s Law. So batteries and solar panels get cheaper and cheaper - even as they get better and better.

But sometimes the definition of what that “better” is can change. Once upon a time the main standard against which computer chips - or superconducting magnets - were measured was their power. But today “better” can just as easily mean something else: lower power or helium consumption.

I think examples like this are rather handy to have in the back of your mind when pondering the world today. When economists fret about a sudden collapse in productivity, it’s quite possible that the metric we’re all focused on is simply the one we used to be fixated with. If you judged the performance of the superconducting magnet sector based purely on how many Teslas each unit could pump out, the chances are you would look at the sector in the coming years and despair. It might look like it’s going backwards!

In actual fact, enormous progress is being made here - as it is elsewhere throughout the Material World. Breakthroughs are being made in the efficiency of these processes. Scientific progress is still happening, with each new generation improving the technology, building on their predecessors’ progress. We just might be focused on slightly different things.

Interesting read and I enjoyed Material World. Helium is used in many essential applications, during a global shortage in 2021 it severely restricted the frequency of several key lab analyses that needed to be done for product quality control at the oil refinery I was working with at the time.

Great piece Ed, thank you very much, and do keep them coming.