How Coal Helped Avert an Environmental Disaster

Or: why technological solutions often turn into their own problems a century or so down the line

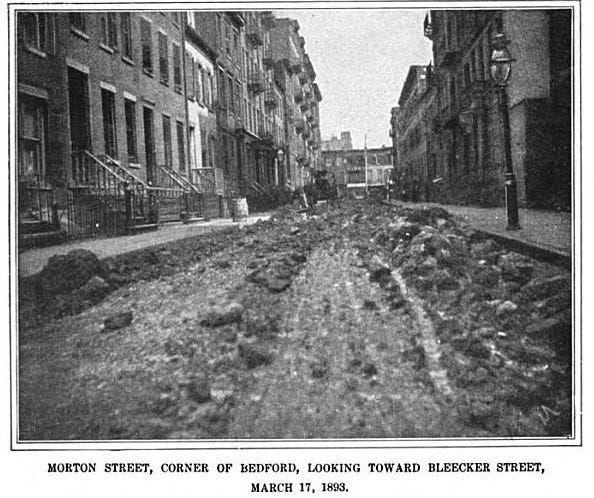

You’ve probably heard the story about how the invention of the automobile was originally held up as an environmental triumph. Back at the tail-end of the 19th century the streets of London and New York were becoming engulfed in horse manure from all the animals pulling cars and carriages around the cities. Health officials calculated that, on the basis of ongoing trends, the cities would soon be completely covered in excrement.

So when the motor vehicle arrived it immediately helped address what was fast becoming a public health nightmare (the problem wasn’t so much the smell but the flies and parasites living in the manure). Roll on a century or so and the motor car - at least the ones with internal combustion engines - had contributed to a fresh environmental problem. The solution to the problem had become a problem.

This was neither the first nor the last episode where an environmental crisis was resolved, only for the solution itself to create its own environmental crisis. Melvin Kranzberg, the late American historian, once laid out “six laws of technology”, the first of which was that “Technology is neither good nor bad; nor is it neutral.” He went on:

Many of our technology-related problems arise because of the unforeseen consequences when apparently benign technologies are employed on a massive scale. Hence many technical applications that seemed a boon to mankind when first introduced became threats when their use became widespread.

The example he gave was the pesticide DDT, introduced to help vanquish one threat - disease-carrying pests - before becoming one of the most vilified chemicals in history, after it emerged that it also threatened the food chains of many birds, fishes and other animals. But an even earlier example is to be found in the history of steelmaking.

The main way of turning iron ore, a rock with lots of iron oxide in it, into a purer form of metallic iron - the kind you can work with and turn into steel (itself an even purer form of iron) - is to throw it into a blast furnace alongside a few other things. The most important “other thing” is a carbon-heavy fuel. The carbon in there, with all its promiscuous chemical tendencies, is the most efficient way of removing oxygen from the iron ore, and up until the 18th century the main carbon-heavy fuel used in blast furnaces was charcoal - a kind of baked carboniferous form of wood.

The upshot was that back in the 16th and 17th century most of the world’s blast furnaces were to be found near forests. Britain’s main hotspots for iron making were the Forest of Dean and the English Midlands. A country’s production of iron was constrained not just by the availability of iron ore but, arguably even more so, by the availability of timber.

It was not for nothing that as of the early 18th century Britain was importing around 20,000 tons of iron each year from Sweden and Russia. They were the European leaders not so much because they had more iron ore (though as it happens they did have lots of iron ore) but also because they had more trees.

England, on the other hand, had plenty of iron ore in pretty decent grades dotted around the country. The main problem was that it simply didn’t have enough trees to make the charcoal with which to make the iron. Indeed, in the 16th and 17th centuries there were periodic panics that the country’s appetite for iron was likely to mean that before long it would be completely denuded of its forests.

The Timber Crisis

This “timber crisis”, as it’s sometimes called, was one of the very earliest environmental panics. For a period the authorities fretted that England would become completely deforested (and, equally worryingly, would run out of the big, thick tree trunks they needed to make masts for their warships). So they regulated how much timber could be removed from forests, plunging the iron industry (and for that matter many other charcoal-reliant businesses) into their own crisis.

The man who, more than any others, is seen as having resolved this crisis was Abraham Darby, an iron worker based in the Midlands who discovered how to use coking coal - a highly carbon-heavy form of baked coal. It’s likely he learnt this from the brewing industry, which had been using coking coal for some time. This is often depicted as one of the watershed moments in the industrial revolution. As Vaclav Smil put it in Still The Iron Age:

This was an epochal change, from the dependence on a resource that was renewable but already in short supply in many regions and whose maximum realistic exploitation could not support the future expansion of iron production to the dependence on a nonrenewable fuel that could be produced inexpensively from abundant coal deposits and whose output could be scaled up to meet any foreseeable expansion of iron industry.

These days Darby’s discovery is sometimes depicted as a moment of infamy: this was when Britain sent the world careering towards a climate catastrophe. What’s invariably forgotten is that back in the 18th and 19th century coal was also helping people avert another environmental catastrophe.

Consider: As of 1820 Belgium, which along with France was quite slow to embrace coal, was giving over more than half of its entire forested areas to making charcoal for iron production. If the UK wanted to use charcoal rather than coal to make its iron today, it would necessitate giving over nearly half the landmass of the country to grow trees, purely for the charcoal for blast furnaces.

These days very few countries still use charcoal to make iron - a notable exception is, perhaps unsurprisingly, Brazil. But trying to do the same thing with all global steel production would entail cutting down half of the Amazon rainforest. It rather underlines the importance of coking coal - metallurgical coal as it’s sometimes called - for steel production. For the time being.

In due course we will find a way to make plentiful iron without coal. It’s a topic I cover at some length in the book. It might mean more electric arc furnaces or more hydrogen direct reduced iron facilities. A new technology will arise which will be feted as helping eliminate carbon emissions and address climate change. The question then is: how soon until this new technology falls foul of Kranzberg’s first law of technology?

PS I’ve spent the past few weeks working on a film for Sky News about Britain’s steel industry. Do watch if interested. There’s also a very long long read.

Potentially yes. But there's a big proviso, which is that as I understand it it's very difficult to run an EAF on wind power alone because it doesn't do strong bursts of energy. You need something else too - hydrogen or batteries maybe...

steel (itself an even purer form of iron)

Error. Steel is an iron carbon alloy that is harder than pure iron